Tel.: +86 13358378970

E-mail: sales6@saulplc.com

Tel.: +86 13358378970

E-mail: sales6@saulplc.com

Jun. 25, 2023

1. Problem Description:

In the industrial field, safety doors are one of the key equipment to prevent accidental injuries and improve production efficiency. Safety doors can ensure the physical health and safety of employees and other relevant personnel, and reduce the risk of accidents during machine operation.

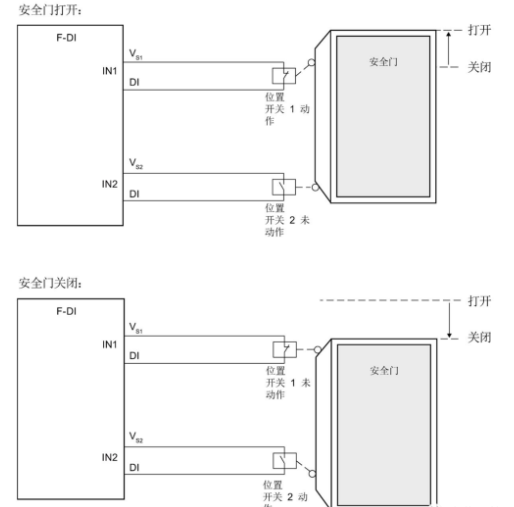

To ensure the safety of workers, a door is installed in the enclosed part of the machine and a safety interlock switch is installed to indicate the status of the door to ensure the safety of the machine or process. Limit switches are the most common interlocking device for safety doors, usually with two opposite limit switches installed on the door. When opening or closing a door, only one limit switch will close, as shown in the following figure.

Figure 1 shows that when the door is opened, switch 1 will be closed and switch 2 will open. When the door is closed, the situation is reversed, with switch 1 open and switch 2 closed. This setting provides an additional level of security and monitoring, as both switches cannot be turned off or on simultaneously. If this situation occurs, it indicates that one of the switches has malfunctioned and will trigger the safety function.

Additionally, according to the redundancy principle, switches 1 and 2 may be dual channel switches, with each switch having two independent channels. In this example, we assume that each switch has dual channels. Therefore, the safety PLC will monitor the system as follows:

The safety PLC will monitor the dual channels of each switch and always keep them in the same position, otherwise internal faults may occur within the switch. The safety PLC will monitor two switches 1 and 2 with each other, always keeping them relative to each other, otherwise one of the switches may malfunction. In any case, the safety PLC will trigger the safety function and confirm all safety conditions until restored.

2. Instruction Introduction:

The process of creating and writing security programs in STEP7 V16 is almost identical to standard programs. You can use F-FBD or F-LAD programming languages to write fail safe FB and FC programs, and use F-DB programming language to create fail safe DBs. STEP7 Safety Advanced V16 provides some typical fail safe application blocks that can be used in security programs. When compiling a security program, it will automatically perform security checks and insert other fault safe blocks for error detection and fault response. This will ensure that faults and errors can be detected and trigger appropriate responses to keep the F system in a safe state or enter a safe state. In addition to security programs, standard user programs can also be run on F-CPU.

Open the security main program block FB1, and call the SFDOOR function block in the security function library on the right.

When one of the signal states in IN1 or IN2 is 0, the enable signal Q will immediately reset to 0 (safety door open). The enable signal can only be reset to 1 when:

Before opening the door, the signal states of input IN1 and IN2 are both 0 (the safety door has been fully opened)

Afterwards, the signal states of input IN1 and IN2 will both be 1 (safety door closed)

When confirmation occurs, follow the input ACK_ Confirm the parameter allocation at NEC for enabling:

If ACK_ NEC=0, confirmation will be automatically performed.

If ACK_ NEC=1, then the rising edge at the input ACK must be used to confirm the enable.

Output ACK_ REQ=1 is used to send a signal indicating that a user confirmation needs to be input on the input ACK in order to confirm. When the door is closed, this command will ACK_ REQ is immediately set to 1. After confirmation, this command will ACK_ Reset REQ to 0.

If the instruction is to recognize whether input IN1 and IN2 are 0 solely due to passivation related F-I/O, then input QBAD needs to be_ IN1 or QBAD_ IN2 provides QBAD signals for related F-I/O or QBAD signals for related channels_ I_ Xx signal/inverted value state. In addition, due to the passivation of F-I/O, it can prevent the safety door from fully opening before confirmation.

• OPEN_ When NEC=0, when the two inputs IN1 and IN2 have signal state 1 (safety door closed) for the first time after re integrating the relevant F-I/O, they will be independent of ACK_ NEC, immediately perform automatic confirmation directly.

• OPEN_ When NEC=1, or if at least one signal state in IN1 and IN2 inputs remains 0 after re integrating the associated F-I/O, it will follow ACK_ NEC performs automatic confirmation or must use a rising edge at the input ACK to enable it. Before confirmation, the signal status of input IN1 and IN2 must first be 0 (the safety door is fully open), and then 1 (the safety door is closed).

The DIAG output will provide non fault safe information about errors for maintenance purposes. This information can be read through operator monitoring and control systems, and can also be evaluated in standard user programs (if applicable).

3. Usage:

When powering on for the first time, although IN1 and IN2 are 1 (the safety door is closed), there is still no output, and ACK=1 will not reset the fault because OPEN_ When NEC=1, the door must be opened and closed again.

After opening and closing the door, ACK_ REQ=1, ACK needs to be given a rising edge to confirm the alarm. Because ACK_ NEC=1.

After resetting, Q=1 and the output is normal.

If there is a time lag between the state changes of switch IN1 and switch IN2, the safety function will be triggered and the output will not be turned on. Under normal circumstances, switch 1 and switch 2 are synchronized. If there is a lag, the system will determine that the switch has malfunctioned, so it will stop outputting.

4. Expand thinking:

SFDOOR function block can only be called in PLC with F. If we want to use it in conventional PLC, can we write a feedback program.

Navigation

Add.: 9D, 9th Floor, Huguang Building, Hubin West Road, Siming District, Xiamen City, Fujian Province, China

Tel.: +86 13358378970

Mob.: +86 13358378970

E-mail: sales6@saulplc.com

WhatsApp: +86 13358378970

Wechat: +86 13358378970